Front

seated rickshaw pedicabs are so much easier to motorize than the kind

with the seats in the rear. Applying the motor to the single rear

drive wheel is like motorizing a bicycle.

There

are advantages to using a single gear reduction with a belt drive,

that will move only 10 to 13mph on your worst hills. Even with two

motors operating at once you will never be able to drive faster than

the legal speed limit for such a vehicle. A high voltage, low amp

controller with high RPM gear reduction is much easier on the motor

by wasting less energy as heat.

You

will have plenty of torque thrust starting across busy intersections.

And you don't need motors running on vertualy flat land. Muscle

power should be used for easy terrain.

But

with 800lbs you will need some fabulous double pad hydraulic

disc brakes. Or you could find out the hard way what happens.

If

you want to go slow without a gear reduction and pull heavy loads get

the CRYASTLYTE X5306 and it will move along at 2-3 mph and pulls like

a mule. But gear reductions are more efficient, and easier to fit

into a legal frame work if the idiot law makers would understand that

gear reductions can be made to stay under the speed limit with out

electronics. Which would result in the impossibility of some wise

guy making a hot rod out the vehicle.

Due

to people ignoring the e-bike laws and the complete lack of

understanding about how powered bikes should be built electric-assist

pedicabs were banned in New York City in January 2008, along with all

other forms of electric vehicles; the city council decided to allow

pedicabs propelled

only

by muscle power. The city of Toronto Canada decided not to issue

permits to electric-assist pedicabs.

If

you want to use as much power as it takes to move 800lbs up a steep

hill in the U.S. you must get a computer-simulation done to prove the

safety of your vehicle. And that costs many thousands of dollars.

So

it is not likely that rickshaws will ever become popular in the land

of milk and honey. Until there is no more petroleum left.

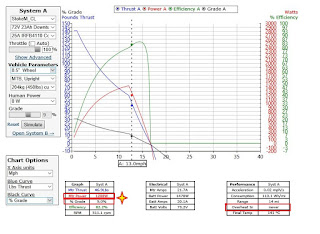

Power

at the wheel needs to be 1497W to go up a 9% grade at 14mph carrying

600lbs, 1294W to go 12mph. When we have only 400lbs, we are at 859W

for 12mph, and 994W for 14mph. This all assumes you are already

traveling at those speeds before you hit the hill.

Had

Oregon law been more like Ontario law, which states that the motor

has to have continuous output power of 500W, you could get around it

by having much higher peak loads for short periods. Talk to a state

congressman and get them to change the law so it states "continuous

output power". Giving you the room for peak bursts up hills.

To

move a heavy vehicle up a steep grade slowly the motor needs a lot of

copper winding to handle the energy wasted as heat. Or you can use a

faster higher voltage and less amperage to achieve the same wattage

at a more efficient RPM. But of course you will need a larger gear

reduction. So most people end up using an over-sized motor that will

waste energy and run the risk of conflict with the laws.

Gears do not

waste energy, they convert torque RPM into thrust, and

increase efficiency by using more momentum

t

http://frankentrikes.com/legacy/RRPage.html

http://www.instructables.com/id/Engineering-a-Power-System-for-Heavy-Cycle-trucks-/

If

you put the two front wheels on a single axle one wheel will be

moving faster than the other and one will skip in a sharp turn.

However if you have each of the front wheels separate from each other

they should turn without making any skipping. Even if you put hub

motors on each of them, and have them on the same accelerator. One

hub motor will still turn faster than the other at the same wattage

because they both use separate controllers.

It

is odd that the builders of these vehicles will not tell you how

these things work. Maybe they don't know how to describe it or they

just think people don't want to know. Yet my blog gets around 2000

page hits a month.

No comments:

Post a Comment